Mud Pump Pistons

Mud Pumps Pistons

- Material: Rubber / Urethane

- Pressure rate: 500psi – 7500psi

- Temperature rate: 180F – 350F

- Bore Hardness: Water/Synthetic based mud

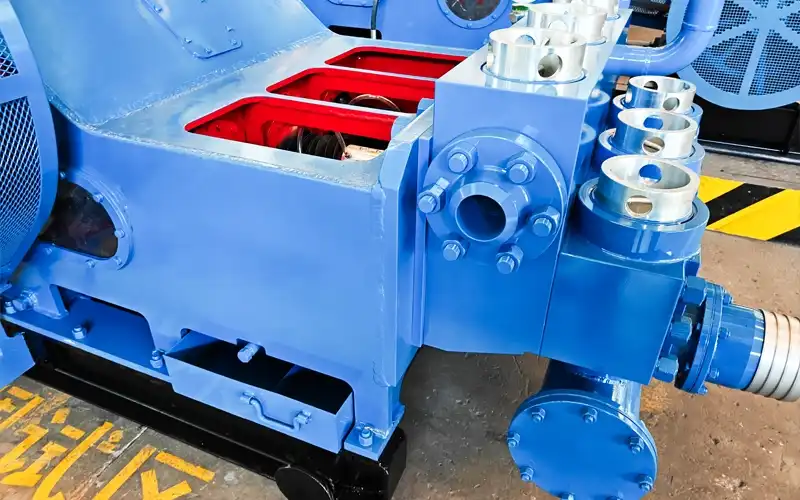

Piston assembly for mud pump is one of the main parts of the hydraulic end system of the mud pump, which generates pressure through the reciprocating movement of the piston in the cylinder liner to accomplish mud compression and transportation. The products are divided into vulcanized one-piece type and assembled type the dimensions are in accordance with APl standard, with high tensile strength, chemical resistance and abra-sion resistance to ensure the service life.

Piston core – made of 42CrMo material forging, with high strength and wear resistance; piston rubber – nitrile rubber or polyurethane rubber, It has good anti-wear, corrosion and high temperature resistance.

Assembled Piston

It consists of piston core and piston rubber etc. The structure is flexible and easy for maintenance and replacement.The piston core is made of high-strength materials such as 42CrMo, while the piston rubber is made of wear-resistant and corrosion-resistant polyurethane to ensure wear resistance and durability.

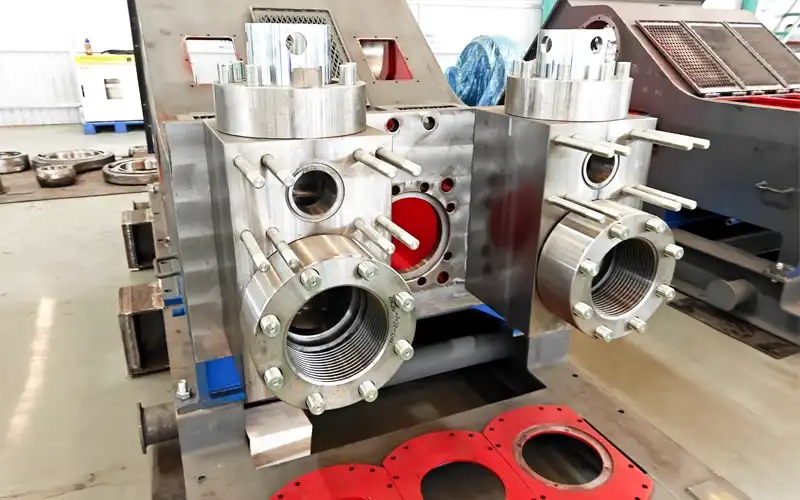

Vulcanized one-piece Piston

The one-time molding through the vulcanization process makes the piston assembly more integrated and has better sealing performance, ensuring its precise movement in the cylinder liner, reducing the risk of offset and leakage, and improving wear resistance and corrosion resistance.

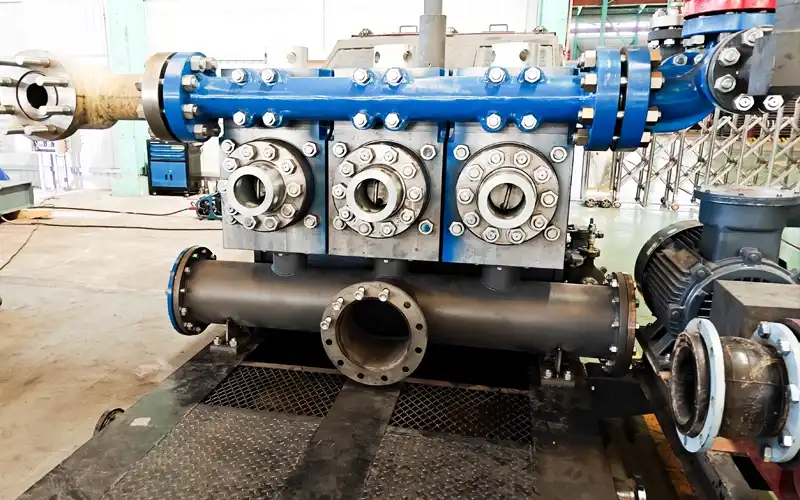

Popular Mud Pump Spare Parts

Below is a partial list of mud pump spares, mud pump replacement parts, and mud pump parts that we have available.

- Bearing Housing

- Bearing Retainer

- Bearing Roller

- Brake Cylinder

- Choke Valve

- Db-550 Stuffing Box

- F-1000 Threaded Ring And Cap

- Crankshaft

- Crosshead Bearing Pin

- Crosshead Liner

- Discharge Module

- Duplex Pistons

- Duplex Pump Liner Packing Cage Assembly

- Fail Safe Piston

- Fluid End Discharge Module

- Fluid End Studs & Nuts

- Full Open Valves

- Gardner Denver Lower Valve Guide

- Gland Brass And Junk Rings

- Gland Nut

- Ideco Mm-700 Duplex Piston Rod

- Ideco T-800 Pony Rod

- Jackshaft Pinion

- Left Hand Crosshead

- Needle Roller Bearing

- Oil Pressure Gauge

- Oil Pump

- Pinion Shaft

- Piston Rod

- Right Hand Crosshead

- Ring Gear

- Rubber Products

- Sheave

- Spherical Roller Bearing

- Sprocket

- Studded Cylinder Module

- Suction Module

- Triplex Pump Piston Rod & Clamp

- Triplex Single Action Piston

- Valve Cover

- Valve Seats

- Wear Plate

- Web Valve Seats

- Web Valves

Superior Craftsmanship

Our aftermarket parts seamlessly integrate with the majority of leading duplex and triplex mud pumps available in the market. Not only do our parts meet industry standards, but our robust warranties and exceptional customer support also provide peace of mind to our valued customers.

Professional Manufacturer

Strict Quality Control

We have a strong quality control team with an advanced laboratory. We test each batch of material and each parts.

Specialities Company

Best Industry Experts

Engel has successively introduced the design and manufacturing technology from world first class oilfield parts, and became the leading player in the industry oilfield field.

Trusted Partners